Advanced Process Parameter Optimization for Compressive Strength of FDM-Printed PETG Using GA-ANFIS

DOI:

https://doi.org/10.5281/zenodo.17034327Keywords:

additive manufacturing, PETG, fused deposition modeling (FDM), compressive strength, GA-ANFIS, process optimizationAbstract

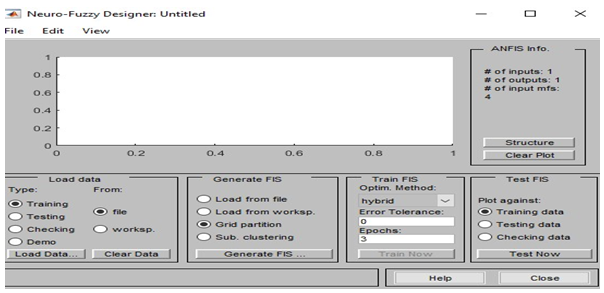

This study investigates the optimization of process parameters to enhance the compressive strength of polyethylene terephthalate glycol (PETG) parts manufactured using Fused Deposition Modeling (FDM). Compression test specimens were fabricated following ASTM D695 standards, with nozzle temperature, infill density, layer height, and printing speed selected as the key input variables. A three-level face-centered central composite design (FCCD) was employed to systematically evaluate their individual and interactive effects on ultimate compressive strength (UCS). Experimental testing revealed that higher infill density and reduced layer height significantly improved compressive performance, with UCS reaching 106.25 MPa under baseline conditions. To further optimize results, a hybrid Genetic Algorithm–Adaptive Neuro-Fuzzy Inference System (GA-ANFIS) framework was implemented, enabling accurate prediction and intelligent optimization of compressive strength. The optimized parameters—224.25 °C nozzle temperature, 88% infill density, 0.15 mm layer height, and 55 mm/s print speed—yielded a maximum UCS of 148.53 MPa, representing a 39.78% improvement over baseline results. The findings demonstrate that intelligent hybrid optimization provides a robust approach for tailoring FDM process parameters, thereby enhancing the structural reliability of PETG components for engineering applications.

Downloads

References

B. Mallikarjuna, Pachipulusu Bhargav, Shivashankar Hiremath, K. G. Jayachristiyan, & N. Jayanth. (2023). A review on the melt extrusion-based fused deposition modeling (FDM): background, materials, process parameters and military applications. doi:10.1007/s12008-023-01354-0.

Dey, A., & Yodo, N. (2019). A systematic survey of FDM process parameter optimization and their influence on part characteristics. Journal of Manufacturing and Materials Processing, 3(3), 64. https://doi.org/10.3390/jmmp3030064

Valvez, S., Silva, A. P., & Reis, P. N. B. (2022). Compressive behaviour of 3D-printed PETG composites. Aerospace, 9(3). https://doi.org/10.3390/aerospace9030124

Kumaresan, R., Samykano, M., Kadirgama, K., Pandey, A. K., & Rahman, M. M. (2023). Effects of printing parameters on the mechanical characteristics and mathematical modeling of FDM-printed PETG. International Journal of Advanced Manufacturing Technology, 128, 3471–3489. https://doi.org/10.1007/s00170-023-12155-w

Iacob, D. V., Zisopol, D. G., & Minescu, M. (2024). Technical-economical study on the optimization of FDM parameters for the manufacture of PETG and ASA parts. Polymers, 16(16), 2260. https://doi.org/10.3390/polym16162260

Mercado-Colmenero, J. M., La Rubia, M. D., Mata-García, E., Rodriguez-Santiago, M., & Martin-Doñate, C. (2020). Experimental and numerical analysis for the mechanical characterization of PETG polymers manufactured with FDM technology under pure uniaxial compression stress states for architectural applications. Polymers, 12(10), Article 2202. https://doi.org/10.3390/polym12102202

Adarsh, S. H., & Nagamadhu, M. (2025). Effect of printing parameters on mechanical properties and warpage of 3D-printed PEEK/CF-PEEK composites using multi-objective optimization technique. Journal of Composites Science, 9(5), 208. https://doi.org/10.3390/jcs9050208

Thakur, A., Vates, U. K., & Mishra, S. (2023, May). Prediction of mechanical properties of FDM printed PLA parts using response surface methodology (Preprint). https://doi.org/10.21203/rs.3.rs-2893592/v1

Yadav, D., Chhabra, D., Garg, R. K., Ahlawat, A., & Phogat, A. (2020). Optimization of FDM 3D printing process parameters for multi-material using artificial neural network. Materials Today: Proceedings, 21, 1583–1591. https://doi.org/10.1016/j.matpr.2019.11.225

Mishra, P., Sood, S., Bharadwaj, V., & Aggarwal, A. (2023). Parametric modeling and optimization of dimensional error and surface roughness of fused deposition modeling printed polyethylene terephthalate glycol parts. Polymers, 15(3), 546. https://doi.org/10.3390/polym15030546

Carvajal-Mena, N., Tabilo-Munizaga, G., Saldaña, M. D. A., Pérez-Won, M., Herrera-Lavados, C., Lemus-Mondaca, R., & Moreno-Osorio, L. (2023). Three-dimensional printing parameter optimization for salmon gelatin gels using artificial neural networks and response surface methodology: Influence on physicochemical and digestibility properties. Gels, 9(9), 766. https://doi.org/10.3390/gels9090766

https://eibos3d.com/blogs/ideas/what-is-petg

Sagar P. (2024). Enrichment in fracture ductility tribological characteristics of magnesium-based nanocomposites fabricated via multi-pass friction stir processing and study of significant parameters. J Mater Eng Perform. https://doi.org/10.1007/s11665-024-09652-8

Bingham D. (n.d.). Handbook of design and analysis of experiments.

Patpatiya P, Shastri A, Sharma S, Chaudhary K, & Bhatnagar V. (2022). ANN-predictive modeling and GA-optimization for minimizing dimensional tolerance in polyjet additive manufacturing. CIRP J Manuf Sci Technol, 38, 320-339.

Allahkarami E, & Nuri OS. (2017). Improving estimation accuracy of metallurgical performance of industrial flotation process by using hybrid genetic algorithm – artificial neural network (GA-ANN). Physicochem Probl Min Process, 53, 366–378.

Nabavi-Kivi A, Ayatollahi MR, Rezaeian P, & Razavi N. (2022). Investigating the effect of printing speed and mode mixity on the fracture behavior of FDM-ABS specimens. Theor Appl Fract Mech, 118, 103223.

Agnelli J, Pagano C, Fassi I, Treccani L, Bignotti F, & Baldi F. (2024). Mechanical behaviour of ductile polymer cellular model structures manufactured by FDM. Mech Mater, 190, 104882

P. Sagar, & A. Handa. (2023). Enhanced strength ductility and wear resistance in a friction stir processing engineered AZ31B/TiC magnesium-based nanocomposites. Can. Metall. Q., 1–19, https://doi.org/10.1080/00084433.2023.2289800

P. Sagar, & A. Handa. (2020). A comprehensive review of recent progress in fabrication of magnesium base composites by friction stir processing technique—A review. AIMS Mater. Sci., 7, 684–704, https://doi.org/10.3934/matersci.2020.5.684

S.K. Gupta, M.K. Mahto, A.R. Raja, M. Vashista, & M.Z.K. Yusufzai. Effect of friction stir processing on the mechanical properties of gas metal arc welded AISI 409 L stainless steel plate. Mater. Today Commun, 41, 111075. https://doi.org/ 10.1016/j.mtcomm.2024.111075

X. Han, H. Li, W. He, G. Wang, X. Zhang, X. Wang, S. Volodymyr, & O. Shcheretskyi. (2024). Study on the microstructure and mechanical properties of hot rolled nano-ZrB2/ AA6016 aluminum matrix composites by friction stir processing. Mater. Today Commun, 40, 109815. https://doi.org/10.1016/j.mtcomm.2024.109815

R. Madadi, S.M.H. Pishbin, S.M. Fatemi, A. Zarei, & J.-H. Cho. (2024). Friction stir processing of pure titanium/nanodiamonds nanocomposites: microstructure, tribological and corrosion properties. Mater. Today Commun., 40, 109975. https://doi.org/ 10.1016/j.mtcomm.2024.109975

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Sunil, Pankaj Khatak, Prem Sagar

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.