Optimization of FDM Process Parameters for Minimizing Specific Wear Rate Using a GA- ANFIS Hybrid Model

DOI:

https://doi.org/10.5281/zenodo.16810194Keywords:

fdm, pin on disc, wear rate, ga-anfisAbstract

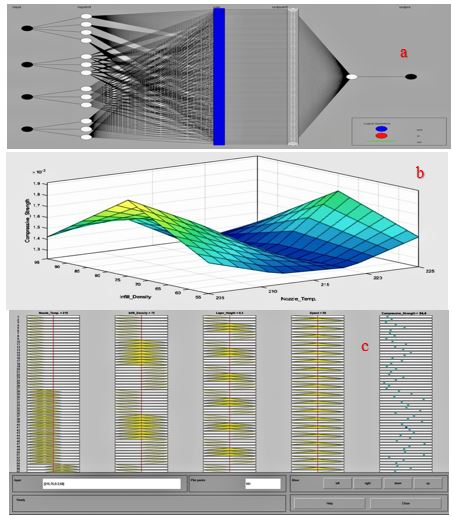

This study investigates the optimization of tribological performance in Fused Deposition Modeling (FDM) fabricated components by focusing on the specific wear rate (SWR) of Polylactic Acid (PLA) specimens. A total of 30 samples were fabricated using a MakerBot Method X 3D printer following ASTM G99 standards, considering four key process parameters: nozzle temperature, infill density, layer height, and printing speed. Wear behavior was evaluated using a Pin-on-Disc apparatus under dry sliding conditions. To predict and minimize SWR, a hybrid GA-ANFIS (Genetic Algorithm–Adaptive Neuro-Fuzzy Inference System) model was employed. The ANFIS framework effectively captured nonlinear relationships among input variables, while GA optimized membership functions to improve prediction accuracy. Experimental results demonstrated that nozzle temperature and layer height had the most significant influence on SWR. The optimized parameter combination achieved a minimum SWR of 8.26 × 10⁻⁴ mm³/N·m, representing a 25.12% reduction compared to non-optimized settings. The proposed hybrid approach proved to be a robust tool for process parameter optimization, enabling enhanced wear resistance and mechanical integrity in FDM-printed parts.

Downloads

References

Attaran, M. (2017). The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Business Horizons, 60(5), 677-688.

Balasubramainian, N. K., Kothandaraman, L., Sathish, T., Giri, J., & Ammarullah, M. I. (2024). Optimization of process parameters to minimize circularity error and surface roughness in fused deposition modelling (FDM) using Taguchi method for biomedical implant fabrication. Advanced Manufacturing: Polymer & Composites Science, 10(1), 2406156.

Bayas, E., Kumar, P., & Harne, M. (2023). Impact of process parameters on mechanical properties of FDM 3D-printed parts: A comprehensive review. European Chemical Bulletin, 12, 708-725.

Chhabra, D., Deswal, S., Kaushik, A., et al. (2023). Analysis of fused filament fabrication parameters for sliding wear performance of carbon reinforced polyamide composite material fabricated parts using a hybrid heuristic tool. Polymer Testing, 118.

Dey, A., & Yodo, N. (2019). A systematic survey of FDM process parameter optimization and their influence on part characteristics. Journal of Manufacturing and Materials Processing, 3(3), 64.

Magdum, Y., Pandey, D., Bankar, A., Harshe, S., Parab, V., & Kadam, M. (2019). Process parameter optimization for FDM 3D printer. International Research Journal of Engineering and Technology (IRJET), 6, 1-6.

Mohamed, O. A., Masood, S. H., & Bhowmik, J. L. (2016). Experimental investigations of process parameters influence on rheological behavior and dynamic mechanical properties of FDM manufactured parts. Materials and Manufacturing Processes, 31, 1983–1994. https://doi.org/10.1080/10426914.2015.1127955

Phogat, A., Chhabra, D., Sindhu, V., & Ahlawat, A. (2022). Analysis of wear assessment of FDM printed specimens with PLA, multi-material and ABS via hybrid algorithms. Materials Today: Proceedings, 62, 37-43.

Popović, M., Pjević, M., Milovanović, A., Mladenović, G., & Milošević, M. (2023). Printing parameter optimization of PLA material concerning geometrical accuracy and tensile properties relative to FDM process productivity. Journal of Mechanical Science and Technology, 37(2), 697-706.

Ramiah, K., & Pandian, P. (2023). Effect of process parameters on the strength of ABS based FDM prototypes: Novel machine learning based hybrid optimization technique. Materials Research Express, 10(2), 025305.

Rouhi Moghanlou, M., Azizian-Farsani, E., Mahmoudi, A., & Khonsari, M. M. (2024). Optimization of FDM parameters for enhanced mechanical properties of chopped carbon fiber-reinforced polymer composites. Progress in Additive Manufacturing, 1-16.

Sagar, P., Rani, S., & Kumar, M. (2025). Hybrid algorithmic techniques for optimizing tensile strength in magnesium-based composites developed via friction stir processing, 1, 1–21.

Şirin, Ş., Aslan, E., & Akincioğlu, G. (2023). Effects of 3D-printed PLA material with different filling densities on coefficient of friction performance. Rapid Prototyping Journal, 29(1), 157-165.

Sharma, K., Kumar, K., Singh, K. R., & Rawat, M. S. (2021, July). Optimization of FDM 3D printing process parameters using Taguchi technique. In IOP Conference Series: Materials Science and Engineering, 1168(1), 012022. IOP Publishing.

Singh, S., Attri, R. K., & Trivedi, S. (2024). Optimization of FDM 3D printing process parameters for improving wear characteristics of PLA-nGr composite using Taguchi DOE. Journal of Materials Engineering and Performance, 1-9.

Solomon, I. J., Sevvel, P., & Gunasekaran, J. J. M. T. P. (2021). A review on the various processing parameters in FDM. Materials Today: Proceedings, 37, 509-514.

Srinivasan, R., Aravindkumar, N., Krishna, S. A., Aadhishwaran, S., & George, J. (2020). Influence of fused deposition modelling process parameters on wear strength of carbon fibre PLA. Materials Today: Proceedings, 27, 1794-1800.

Srivastava, P., & Singh, V. P. (2024). Optimizing tribological performance of 3D-printed poly (lactic acid) components through process parameter analysis. Iranian Polymer Journal, 1-18.

Vasumathi, M., Karupaiah, V., & Narayanan, V. (2024). Effect of process parameters on mechanical and tribological characteristics of FDM printed glass fiber reinforced PLA composites. Rapid Prototyping Journal, 30(9), 1859-1875.

Wittbrodt, B., & Pearce, J. M. (2015). The effects of PLA color on material properties of 3-D printed components. Additive Manufacturing, 8, 110-116.

Yadav, D., Chhabra, D., Garg, R. K., Ahlawat, A., & Phogat, A. (2020). Optimization of FDM 3D printing process parameters for multi-material using artificial neural network. Materials Today: Proceedings, 21, 1583-1591.

Yaman, P., Ekşi, O., Karabeyoğlu, S. S., & Feratoğlu, K. (2024). Effect of build orientation on tribological and flexural properties of FDM-printed composite PLA parts. Journal of Reinforced Plastics and Composites, 43(1-2), 97-110.

Yao, T., Deng, Z., Zhang, K., & Li, S. (2019). A method to predict the ultimate tensile strength of 3D printing polylactic acid (PLA) materials with different printing orientations. Composites Part B: Engineering, 163, 393-402.

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Nitesh Pingal, Munish Gupta, Prem Sagar

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.