African Oil Bean Seed Oil Biodiesel Optimization Production via the Technique of Response Surface Methodology-Genetic Algorithm (RSM-GA) and RSM

DOI:

https://doi.org/10.5281/zenodo.15853705Keywords:

biodiesel, transesterification, fatty acid alkyl esters (FAAE), optimizationAbstract

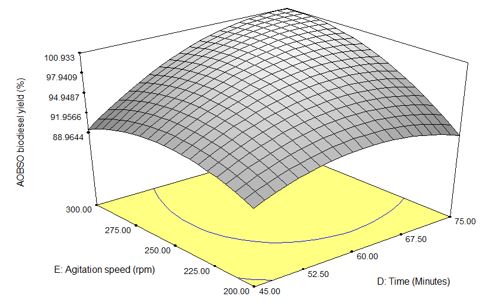

This article focuses on optimized production of biodiesel from African Oil Bean Seed Oil, an indigenous African tropical tree of the leguminosea family, using response surface methodology (RSM) and response surface methodology-genetic algorithm (RSM-GA). Transeterification method was adopted using sodium hydroxide (NaOH) catalyst and methanol (alcohol). The extracted oil was pre-treated due to its high free fatty acid FFA contentFrom the research findings, the physiochemical properties of AOBSO are within ASTM ranges. The process parameters investigated were agitation speed, methanol/oil molar ratio, reaction time, reaction temperature, and catalyst concentration. RSM and RSM-GA gave nearly identical optimal results, with RSM-GA producing the better yield. Agitation speed of 225 rpm, methanol/oil molar ratio of 6.2:1, reaction time of 60 minutes, reaction temperature of 60oC and catalyst concentration of 0.775%wt were therefore the optimal parameters for RSM-GA.

The yield of methyl esters (FAAE) under these optimal process parameters was 99.75%.

Downloads

References

Saka, S., & Kusdiana, D. (2001). Bio-diesel Fuel from Rapeseed Oil as Prepared in Supercritical Methanol. Fuel, 80, 225-230.

Aderemi, B.O., & Hameed, B. H. (2010). Production of biodiesel from palm oil. Nigeria Society of Chemical Engineers Proceedings, 40, 135-143.

Wangkhem Robinson Singh, & Huirem Neeranjan Singh. (2024). CCd-RSM optimization of biodiesel production from waste cooking oil using Angulyagra oxytropis and Bellamya crassa snail shell-based heterogeneous catalysts. Fuel.

Ofoefule, A. U., Ibeto, C. N., Okoro, U. C., & Onukwuli, O. D. (2013) Biodiesel production from tigernut (Cyperus esculentus) oil and characterization of its blend with petro-diesel. Physical Science International Journal, 145-153.

Xianglin Hou, Yongqin Qi, Xingang Qiao, Guofu Wang, Zhangfeng Qin, & Jianguo Wan. (2007). Lewis acid-catalyzed transesterification and esterification of high free fatty acid oil in subcritical methanol. Korean Journal of Chemical Engineering.

Rahmath Abdulla, Eryati Derman, Thivyasri K. Mathialagan, & Abu Zahrim Yaseret. (2022). Biodiesel production from waste palm cooking oil using immobilized candida rugosa lipase. Sustainability.

Wisdom C. Ulakpa, Ruth O. E. Ulakpa, Michael C. Egwuyenga, & Titus C. Egbosiub. (2022). Transesterification of non-edible oil and effects of process parameters on biodiesel yield. Cleaner Waste Systems.

Enujiugha, V.N., & C.T. Akanbi. (2005). Compositional changes in African oil bean (Pentaclethra macrophylla Benth) seeds during thermal processing. Pak. J. Nutr., 4, 27-31.

Achinewhu, S.C., U.O. Anthony, & U.E. Offiong. (1998). Nutritional quality F plants foods. Post-Harvest Research Unit, University of Benin, Nigeria, pp. 134-159.

Ikhuoria, E. U., Aiwonegbe, A. E., Okoli, P., & Idu. M. (2008). Characterization and composition of African oil bean seed. Journal of Applied Science, 8(7), 1337-1339.

Fidelis Azi, Helen A. Njoku, Esther I. David, Michael O. Odo, Veronica N. Nwobasi, Chuanhai Tu, & Mingsheng Dong. (2019). Effect of processing aid on the chemical composition and metagenomics of fermented African oil bean seed (Pentaclethra Macrophylla.Benth). LWT.

Ogunsuyi, H.O. (2012). Acid and base catalysed transesterification of mango (Mangifera Indica) seed oil to biodiesel. IOSR Journal Applied Chemistry (IOSRJAC), 18-22.

Ogunsuyi, H.O., & Daramola, B. M. (2013). Evaluation of almond seed oil as viable feedstock for biodiesel fuel. International Journal of Biotechnology Resources, 1(8), 120-127

Aguoma Chinedu Chris, Ajiwe Vincent Ishmael Egbulefu, Okoye Patrice-Anthony Chudi, Ike Ozoemena Christian et al. (2023). A comparative study of transesterification of hydnocapus weightiana seed oil using calcined and acid activated natural heterogeneous catalyst and its kinetic study. American Journal of Analytical Chemistry.

Ekpo, S. A., B. A. Etuk, & N. O. Eddy. (2009). Effect of some local additives on the chemical constituent of palm oil. Journal of Applied Sciences and Environmental Management.

Elendu Collins Chimezie, Zhioong Wang, Yun Yu, Ude Callistus Nonso, Pei-Gao Duan, & Krzysztof Kapsuta. (2023). Yield optimization and fuel properties evaluation of the biodiesel derived from avocado pear waste. Industrial Crops and Products.

Ogunsuyi, H.O., & Daramola, B. M. (2013). Evaluation of almond seed oil as viable feedstock for biodiesel fuel. International Journal of Biotechnology Resources, 1(8), 120-127.

Dominic O. Onukwuli, Jonah C. Umeuzuegbu, Callistus N. Ude, & Chukwuemeka C. Nwobi-Okoye. (2020). Homogeneous catalyzed tranesterification of neem seed oil to biodiesel and its kinetic modeling. Biofuels, Bioproducts and Biorefining.

Dominic Okechukwu Onukwuli, Lovet Nwanneka Emembolu, Callistus Nonso Ude, Sandra Ogechukwu Aliozo, & Matthew Chukwudi Menkit. (2017). Optimization of biodiesel production from refined cotton seed oil and its characterization. Egyptian Journal of Petroleum.

Myers, R. H., Montgomery, D. C., & Anderson-Cook, C. (2009) Response surface methodology: Product and process optimization using designed experiments. New York: John Wiley & Sons.

Ikenna Chibuzor Emeji, Michael Kumi, & Reinout Meijboom. (2024). Performance evaluation of benzyl alcohol oxidation with butyl hydroperoxide to benzaldehyde using the response surface methodology, artificial neural network, and adaptive neuro-fuzzy inference system model. ACS Omega.

Okwudili E. Umeagukwu, Dominic O. Onukwuli, & Callistus, N, Ude. (2023). Methanolysis of African pear seed oil catalyzed with acid activated empty palm fruit bunch ash: Optimization and sensitivity analysis. Cleaner Energy Systems.

Wangkhem Robinson Singh, & Huirem Neeranjan Singh. (2024). CCd-RSM optimization of biodiesel production from waste cooking oil using angulyagra oxytropis and bellamya crassa snail shell-based heterogeneous catalysts. Fuel.

Fatah H. Alhassan, Umer Rashid, & Y. H. Taufiq Yap. (2014). Ferric-manganese doped sulphated zirconia nanoparticles catalyst for single-step biodiesel production from waste cooking oil: Characterization and optimization. International Journal of Green Energy.

M. Ude Callistus, N. Igwilo Christopher, Nwosu-Obieogu Kenechi, & C. Nnaji Patrick et al. (2023). Optimization of dual transesterification of jatropha seed oil to biolubricant using hybridized response surface methodology (RSM) and adaptive neuro-fuzzy infeence system-genetic algorithm (ANFIS-GA). Sustainable Chemistry for the Environment.

Adebisi A. Okeleye, & Eriola Betiku. (2019). Seed oil extraction: comparative evaluation of solvents, modeling, and optimization techniques. Chemical Engineering Communications.

Eriola Betiku, Victoria O. Odude, Niyi B. Ishiola, Ayorinde Bamimore, Ajiboye S. Osunleke, & Adebisi A. Okeleye. (2016). Predictive capability evaluation of RSM, ANFIS and ANN: A case of reduction of high free fatty acid of palm kernel oil via esterification process. Energy Conversion and Management.

Onukwuli Dominic Okechukwu, Nwosu Obieogu Kenechi, Ezeugo Joseph, & Ude Callistus Nonso. (2023). Soft computing prediction of linseed oil transesterification process via clay-doped barium chloride catalyst. Process Integration and Optimization for Sustainability.

Kafuku, G. (2009). Biodiesel production from cotton mrgalocarpus oil and its process optimization. Fuel.

Hui Lin, Lingyan Su, Yong Shao, & Lubin Zou. (2012). Biodiesel production catalyzed by cinder supported CaO KF particle catalyst. Fuel.

Dominic O. Onukwuli, Jonah C. Umeuzuegbu, Callistus N. Ude, & Chukwuemeka C. Nwobi-Okoye. (2020). Homogeneous catalyzed tranesterification of neem seed oil to biodiesel and its kinetic modeling. Biofuels, Bioproducts and Biorefining.

Farooq, Muhammad, Anita Ramli, & Duvvuri Subbarao. (2013). Biodiesel production from waste cooking oil using bifunctional heterogeneous solid catalysts. Journal of Cleaner Production.

Masoud Zabeti, Wan Mohd Ashri Wan Daud, & Mohamed Kheireddine Aroua. (2010). Biodiesel production using alumina-supported calcium oxide: “An optimization study”. Fuel Processing Technology.

Hamze, Hoda, Mandana Akia, & Farshad Yazdani. (2015). Optimization of biodiesel production from waste cooking oil using response surface methodology. Process Safety and Environmental Protection.

Encinar, J. M.. (2011). Rape seed oil transesterification over heterogeneous catalysts. Fuel Processing Technology.

Wisdom C. Ulakpa, Ruth O. E. Ulakpa, Michael C. Egwuyenga, & Titus C. Egbosiuba, (2022). Transesterification of Non-edible Oil and Effects of Process Parameters on Biodiesel Yield. Cleaner Waste Systems.

Jahangir Chowdhury, Priti Kumar Roy, & Siddhartha Datta. (2019). Comparative study on biodiesel production from Jatopha Curcas oil by supercritical and chemical catalytic method: a mathematical approach. Energy Sources, Part A: Recovery, Utilization and Environmental Effects.

Juan A. Melero, L. Fernando Bautista, Jose Iglesias, Gabriel Morales, Rebecca Sanchez-Vazquez, & Irene Suarez-Marcos. (2010). Biodiesel production over arenesulfonic acid-modified mesostructured catalyts: Optimization of reaction parameters using response surface methodology. Topics in Catalysis.

Callistus Nonso Ude, Dominic Okechukwu Onukwuli, Jonah Chukwudi Umeuzuegbu, & Chinemelum Chukwujekwu Chukwuka. (2020). Heterogenous catalyzed methonolysis of gmelina seed oil to biodiesel. Chemical Engineering & Technology.

Dharma, S., H. H. Masjuki, Hwai Chyuan Ong, A. H. Sebayang, A. S. Silitonga, F. Kusumo, & T. M. I. Mahlia. (2016). Optimization of biodiesel production process for mixed Jatropha curcasCeiba pentandra biodiesel using response surface methodology. Energy Conversion and Management.

M. C. Ndukwu, & C. I. Onyeoziri. (2020). African oil bean seed as feedstock for bio-oil and biodiesel production and the effects of thermal pre-treatments on the quality of the bio-oil. Biomass Conversion and Biorefinery.

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Oghoghoreva Edison Ogwor, Okechukwu D Onukwuli, Callistus N Ude, Emifoniye Elvis, Utu G Ochuko

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.