Structural Simulation Analysis of a Hybridized Composite Pulley using SolidWorks Simulation Technique

DOI:

https://doi.org/10.5281/zenodo.14848687Keywords:

composite, hybridized pulley, finite element, method, a36 steel, solidworksAbstract

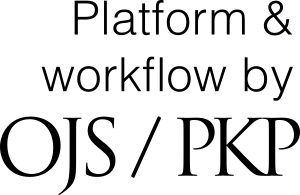

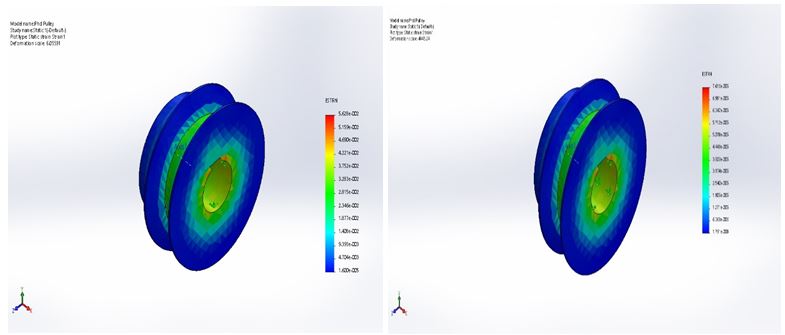

This study explores the simulation and finite element analysis of a pulley hybridized composite reinforced (with silica sand and soda-lime glass) A36 grade steel and cast iron steel. SolidWorks simulation techniques were used in this study for the numerical analysis of stress-strain distribution and deformation under applied torque. A simulation study was carried out under the three different materials. The hybridized pulley had the highest strain and displacement of 5.63×10⁻² and 1.258×10⁻² for cast iron but the least weight of 1.8659N for the hybridized pulley. The material of choice based on displacement was cast iron pulley material, but based on weight and operational sufficiency, the hybridized pulley material can also be chosen because there were no large deviations from the strain and displacement analysis.

Downloads

References

Ezechukwu V. C. (2024). Hybridization effect on thermo-mechanical behaviour of epoxy/breadfruit seed shell ash particles and momordica angustisepala fiber composites for high-temperature devices application. Iconic Research and Engineering Journals, 7(11), 213-223.

Braide, T.K., Nwobi-Okoye, C.C., & Ezechukwu, V.C. Taguchi-Grey multi-response optimization of wear parameter of new nanocomposite formulation of Al–Si–Mg alloy reinforced with synthesis carbon nanotube and periwinkle shell nanoparticles. Int J Adv Manuf Technol, 120, 8363–8375. https://doi.org/10.1007/s00170-022-09163-7

Braide T. Kelsy, Chidozie Chukwuemeka Nwobi-Okoye, Vincent Chukwuemeka Ezechukwu, & Remy Uche. (2023). Multi objective optimization of novel Al-Si-Mg nanocomposites: A Taguchi ANN-NSGA-II Approach. Journal of Engineering Research. https://doi.org/10.1016/j.jer.2023.10.008

Obinwa,C C., Ezechukwu, V C., & Nwosu, A W. (2024). Optimization and analysis of mechanical properties (Tensile Strength) in a developed plantain hybrid fibre reinforced composite (PHFRC). International Journal of Engineering Research And Development, 20(12), 109-119.

Zhao, T., Qi, Z., & Wang, G. et al. (2024). An analysis method for rope-driven multibody systems with pulley blocks. J Mech Sci Technol, 38, 6471–6487. https://doi.org/10.1007/s12206-024-1105-x

Qianhui Fan, Huanqing Duan, & Xiaojun Xing. (2024). A review of composite materials for enhancing support, flexibility and strength in exercise. Alexandria Engineering Journal, 94, 90-103. https://doi.org/10.1016/j.aej.2024.03.048

Jamila S. Alzahrani, Z.A. Alrowaili, I.O. Olarinoye, Ebru Yılmaz, Fatih Çalıskan, Sultan Alomairy, & M.S. Al-Buriahi. (2024). Zircoborate glass-ceramic composite reinforced with aluminum oxynitride: Microstructural evolution, physical properties, and charged radiation attenuation analysis. Ceramics International, 50(20), Part A, 37633-37642. https://doi.org/10.1016/j.ceramint.2024.07.122

Jiaying Wei, Linyuwen Ke, Peng Wang, Weiwen Li, & Christopher K.Y. Leung. (2024). Microstructure, mechanical properties and interaction mechanism of seawater sea-sand engineered cementitious composite (SS-ECC) with Glass Fiber Reinforced Polymer (GFRP) bar. Composite Structures, 343, 118302. https://doi.org/10.1016/j.compstruct.2024.118302

Rounak Mahakul, Dhirendra Nath Thatoi, Sasanka Choudhury, & Pragyan Patnaik. (2021). Design and numerical analysis of spur gear using SolidWorks simulation technique. Materials Today: Proceedings, 41(2), 2021, 340-346. https://doi.org/10.1016/j.matpr.2020.09.554

Kumar Vardaan, & Paras Kumar. (2023). Tribological parameters analysis of cam and follower pair used in IC engine using ANSYS. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2023.05.525

Mehmet Bahadır Çetinkaya,& Muhammed İşci. (2023). ANSYS based analysis of multi-level parabolic leaf spring systems. Alexandria Engineering Journal, 73, 109-121. https://doi.org/10.1016/j.aej.2023.04.043

V. Mohanavel, S. Prasath, M. Arunkumar, G.M. Pradeep, & S. Surendra Babu. (2021). Modeling and stress analysis of aluminium alloy based composite pressure vessel through ANSYS software. Materials Today: Proceedings, 37(2), 1911-1916. https://doi.org/10.1016/j.matpr.2020.07.472

Yiming Yan, Liqiang Zhang, Xiaorong Luo, Ronghu Zhang, Qinglu Zeng, & Shuai Jiang. (2024). Effects of grain crushing, ductile grain deformation, and grain packing texture on sandstone compaction: Implications from DEM numerical simulations. Geoenergy Science and Engineering, 237, 212803. https://doi.org/10.1016/j.geoen.2024.212803

S.S. Godara, Vinayak Brenia, Amit Kumar Soni, Rupender Singh Shekhawat, & K.K. Saxena. (2022). Design & analysis of connecting rod using ANSYS software. Materials Today: Proceedings, 56(4), 2022, 1896-1903. https://doi.org/10.1016/j.matpr.2021.11.166

Iñigo Urcelay Oca, Brian Lau Verndal Bak, Albert Turon, & Esben Lindgaard. (2024). An ANSYS user cohesive element for the modelling of fatigue initiation and propagationof delaminations in composite structures. Engineering Fracture Mechanics, 308, 110337. https://doi.org/10.1016/j.engfracmech.2024.110337

Kumar Vardaan, & Paras Kumar. (2022). Design, analysis, and optimization of thresher machine flywheel using Solidworks simulation. Materials Today: Proceedings, 56(6), 3651-3655. https://doi.org/10.1016/j.matpr.2021.12.348

Shashi Bahl, & Ashok Kumar Bagha. (2021). Finite element modeling and simulation of the fiber–matrix interface in fiber reinforced metal matrix composites. Materials Today: Proceedings, 39(1), 70-76. https://doi.org/10.1016/j.matpr.2020.06.160

Ezechukwu, V. C., Onyenanu, I. U., Ayadinuno, G., & Agwaziam, J. O. (2025). Structural simulation analysis of the developed hybrid of Momordica angustisepala fiber and Breadfruit seed-shell particles composites Bolted Flanges. IPS Journal of Engineering and Technology, 1(1), 13–20. https://doi.org/10.54117/ijet.v1i1.2

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Emifoniye Elvis, Chiedozie Chukwuemeka Nwobi-okoye, Vincent Chukwuemeka Ezechukwu

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.