Taguchi Method for High Speed Cutting Forces

DOI:

https://doi.org/10.54741/asejar.1.4.2Keywords:

forces, taguchi method, speedAbstract

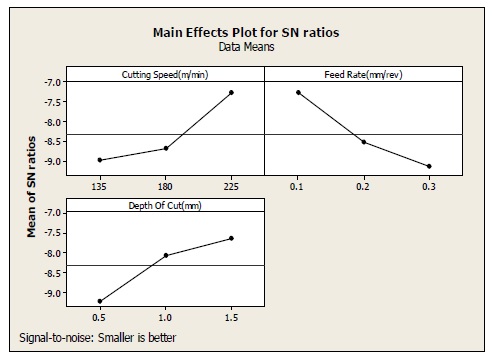

The purpose of this study is to determine experimentally the influence of tool rake angle on EN 31Steel, MS, and Aluminum specimens as work piece materials and carbide as a tool material during a turning process. It has been found that cutting speed, feed rate, and depth of cut are all affected by the rake angle (00-160). In order to estimate the impact of material type on primary cutting force, the same cutting conditions, tool parameters, and tool material were used in many experiments on the three Specimen materials. As the tool rake angle increases from 00 to 160, the primary cutting force decreases for EN 31, M.S. specimens, however the main cutting force increases for Aluminum specimens as the angle rises. This is due to the material of the workpiece. Cutting force is highest at EN 31 specimens and MS specimens, and lowest at the aluminium specimens, according to experimental results. In this thesis, we're also looking for the best control settings to minimise surface roughness.. During a turning operation, the parameters of the process, such as cutting speed, feed rate, and cut depth, will be examined. In this study, Taguchi's design of experiments was used to analyse surface roughness using different turning process parameters of EN-31 Steel, MS, and Aluminum in a turning operation with rake angles of 40 and a S/N ratio of 1.

Downloads

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2022 Kalyani N. Neve

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.