Comparative Analysis of Experimental -Based Wear Rate Investigation of Different Coatings on Nitrided AISI H13 Tool Steel

DOI:

https://doi.org/10.5281/zenodo.15782893Keywords:

taguchi method, analysis of variance, signal to noise (s/n) ratio, optimization, wear rate, coating typeAbstract

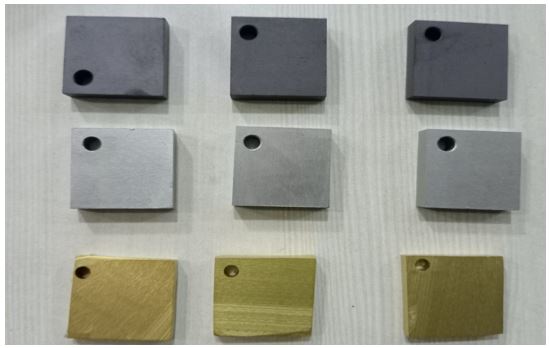

The research investigates the tribological behavior of Titanium Carbide (TiC) and Chromium Nitride (CrN) and Aluminum Titanium Nitride (AlTiN) coatings used on gas-nitrided AISI H13 tool steel when operating under multiple conditions. The Taguchi L9 orthogonal design evaluated how coating type together with temperature (40–50 °C) and load (5–15 N) affect wear rate measurements. A tribometer tester performed the wear tests and were determined by applying the circular segment method to assess the cross-sectional area of the tracks formed during testing.. The multiple linear regression prediction model for wear rate performance exhibited an error margin of less than 10% throughout every experimental trial. The statistical results from analysis of variance (ANOVA) showed coating type to be the main contributor to wear variation (p = 0.002). Within the set of tested coatings AlTiN established the highest degree of wear resistance during optimized conditions. The verification tests confirmed the accurate forecasting capabilities of the predictive model for regression while showing that duplex surface modifications work properly. Results show that using AlTiN-coated nitrided AISI H13 steel makes it possible to deploy these tools in demanding high-temperature applications which need exceptional wear protection.

Downloads

References

Ning, Dongdong, Ao Zhang, & Hui Wu. (2019). Enhanced wear performance of cu-carbon nanotubes composite coatings prepared by jet electrodeposition. Materials. https://doi.org/10.3390/ma12030392.

Patil, Amit, Ganesh Walunj, Furkan Özdemir, Rajeev Gupta, & Tushar Borkar. (2021). Tribological behavior of carbon-based nanomaterial-reinforced nickel metal matrix composites. Materials. https://doi.org/10.3390/ma14133536.

Prabhu, T. Ram, V.K. Varma, & Srikanth Vedantam. (2014). Tribological and mechanical behavior of multilayer Cu/SiC + Gr hybrid composites for brake friction material applications. Wear. Elsevier BV. https://doi.org/10.1016/j.wear.2014.06.006.

Raghuram, Harsha, Christian Katsich, K. Pichelbauer, Kurt Koschatzky, Carsten Gachot, & Ulrike Cihak-Bayr. (2019). Design of wear and corrosion resistant FeNi-graphite composites by laser cladding. Surface and Coatings Technology. Elsevier BV. https://doi.org/10.1016/j.surfcoat.2019.124897.

Stalin, B., M. Ravichandran, Alagar Karthick, M. Meignanamoorthy, G.T. Sudha, S. Karunakaran, & Bharani Murugesan. (2021). Investigations on microstructure, mechanical, thermal, and tribological behavior of Cu-MWCNT composites processed by powder metallurgy. Journal of Nanomaterials. https://doi.org/10.1155/2021/3913601.

Sun, Xun, Rui‐Fen Guo, Alateng Shaga, Zhijie Hu, Ping Shen, Zhiqiang Zhang, & Qi‐Chuan Jiang. (2020). Preparation and characterization of high damage-tolerance nacre-inspired magnesium alloy matrix composites with high carbon nanotube contents. Carbon. Elsevier BV. https://doi.org/10.1016/j.carbon.2020.02.072.

Mrs. Jayshri Pawar, Dr. Ravindra R. Malagi, Dr. Manoj Jadhav, & Dr. Sushant Patil. (2024). Natural fiber thermoplastic composites for mechanical and biodegradability properties. AJBR, 27(3S), 5241–5247. doi:10.53555/AJBR.v27i3S.3306.

Sushant M. Patil, Dr. R. R. Malagi, & R. G. Desavale. (2023). Investigation of vibration levels of antifriction bearing with right-angled faults on inner race and rolling element under diverse load conditions. AIP Conf. Proc., 2716, 030014. https://doi.org/10.1063/5.0129979.

Suyash A. Jangam, Aniket A. Patil, & Sushant M. Patil. 92021). Modeling and development of multi-arm robot using CATIA for pick and place operation to adapt ease in work. International Research Journal of Engineering and Technology (IRJET), 08(05), 2822-2827. https://shorturl.at/8OZs3.

I.M. Jamadar, S.M. Patil, S.S. Chavan, G.B. Pawar, & G.N. Rakate. (2013). Thickness optimization of inclined pressure vessele using non linear finite element analysis using design by analysis approach. International Journal of Mechanical Engineering and Technology (IJMET), 3(3), 682-689.

Sushant Mohan Patil. (2022). Studies on the non-linear dynamic modelling of antifriction bearings for fault diagnosis. http://hdl.handle.net/10603/543017.

Fang, B.Z. et al. (2022). Upgrading the state-of-the-art electrocatalysts for proton exchange membrane fuel cell applications. Adv. Mater. Interfaces, 9, 2200349.

Zhao, M.M. et al. (2022). Constructing porous nanosphere structure current collector by nitriding for lithium metal batteries. J. Energy Storage, 47, 103665.

Arabczyk, W. et al. (2022). Oscillatory mechanism of α-Fe (N)↔ γ’-Fe₄N phase transformations during nanocrystalline iron nitriding. Materials, 15, 1006.

Sun, J.Q. et al. (2022). In situ preparation of Nano-Cu/Microalloyed gradient coating with improved antifriction properties. Coatings, 12, 1336.

Wang, Y. et al. (2022). Advances in latest application status, challenges, and future development direction of electrospinning technology in the biomedical. J. Nanomater., 3791908.

Xu, W.C. et al. (2022). Recent advances in open-cell porous metal materials for electrocatalytic and biomedical applications. Acta Metall. Sin., 58, 1527–1544.

García Caballero, F. et al. (2022). Encyclopedia of materials: Metals and alloys. Amsterdam: Elsevier.

Sundaram, R. Meenakshi, Takeo Yamada, Kenji Hata, & A. Sekiguchi. (2017). Electrical performance of lightweight CNT-Cu composite wires impacted by surface and internal Cu spatial distribution. Scientific Reports. Nature Portfolio. https://doi.org/10.1038/s41598-017-09279-x.

Swamy, Amit, C. Shamitha, Manoj Kumar Singh, Moti Lal Rinawa, K.V. Pradeep Kumar, Sami Al Obaid, Mahadeo A. Mahadik, Saleh Alfarraj, & Mebratu Markos. (2022). Experimental investigations on the wear behaviour of eutectic Al-7075/CNT/Graphite composites manufactured by a combination of two-stage stir and squeeze casting techniques. Journal of Nanomaterials. https://doi.org/10.1155/2022/7995261.

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Umesh Subhash Patharkar, Sunil Apparao Patil

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.