Improving Wear Resistance of Epoxy Composites via Ceramic Nanoparticle Reinforcements by using Taguchi Technique

DOI:

https://doi.org/10.5281/zenodo.15575896Keywords:

tribometer, anova, tio2, al2o3, tribological propertiesAbstract

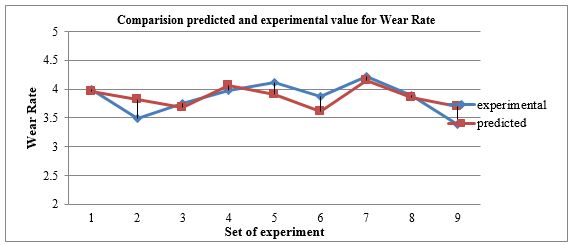

In this study, the weight percentages of various composites are added to epoxy resin coating material with a fixed amount of ceramic particles in order to improve the coating's mechanical and tribological qualities. Prepared were test specimens of pure epoxy resins with varying reinforcement weight percentages (4%, 6%, and 8%). The configuration of a tribometer is used to examine the material's wear properties by conducting various tests on a polymer matrix composite. The results show that adding TiO2 (titanium dioxide) and creamic Al2O3 (aluminum oxide) reinforcement material significantly improves the mechanical and tribological characteristics of the newly developed epoxy paint composite. On a tribometer with variable load and temperature, the wear resistance of a specimen was examined. According to the data, both reinforcements in epoxy resins result in a lower wear rate than pure epoxy. An analysis of variance, also known as an ANOVA, was carried out in order to ascertain the relevance of the operating parameters to the performance qualities that were being taken into account. Further experimentation has been conducted to validate the performance of optimal parameters. Finally, the confirmation test to compare the projected value of the wear rate to the experimental value has been conducted.

Downloads

References

Giliopoulos D, Zamboulis A, Giannakoudakis D, Bikiaris D, & Triantafyllidis K. (2020). Polymer/metal organic framework (MOF) nanocomposites for biomedical applications. Molecules, 25, 185.

Khatri B, Lappe K, Noetzel D, Pursche K, & Hanemann T. (2018). A 3D-printable polymer-metal soft-magnetic functional composite—Development and characterization. Materials, 11, 189.

V. Manubolu, & D. Vanimireddy. (2023). Experimental study on mechanical behaviour of arhar-reinforced composites using GRA with PCA. Int. J. Exp. Res. Rev., 36, 232-243.

Seidi F, Jouyandeh M, Taghizadeh M, Taghizadeh A, Vahabi H, & Habibzadeh S, et al. (2020). Metal-organic framework (MOF)/epoxy coatings: A review. Materials, 13, 2881.

Lashgari SM, Yari H, Mahdavian M, Ramezanzadeh B, Bahlakeh G, & Ramezanzadeh M. (2021). Application of nanoporous cobalt-based ZIF-67 metal-organic framework (MOF) for construction of an epoxy-composite coating with superior anti-corrosion properties. Corrosion Science, 178, 109099.

Deng W, Hou G, Li S, Han J, Zhao X, & Liu X, et al. (2018). A new methodology to prepare ceramic-organic composite coatings with good cavitation erosion resistance. Ultrasonics Sonochemistry, 44, 115-119.

A. Jain, C. S. Kumar, & Y. Shrivastava. (2023). An effort for identifying suitable machining range during drilling of a novel al-based composite using electric discharge machine. Int. J. Exp. Res. Rev., 36, 327-346.

Deng W, Zhao X, Ren Y, Hao E, Han J, & An Y, et al. (2019). Influence of epoxy resin on the microstructure and cavitation erosion of as-sprayed 8YSZ coating. Ceramics International, 45, 5693-5702.

Li M, Li H, Lan JL, Yu Y, Du Z, & Yang X. (2018). Integrative preparation of mesoporous epoxy resin–ceramic composite electrolytes with multilayer structure for dendrite-free lithium metal batteries. Journal of Materials Chemistry A, 6, 19094-19106.

Nakonieczny DS, Antonowicz M, & Paszenda Z. (2020). Surface modification methods of ceramic filler in ceramic-carbon fibre composites for bioengineering applications–a systematic review. Reviews on Advanced Materials Science, 59, 586-605.

Selim MS, Yang H, Li Y, Wang FQ, Li X, & Huang Y. (2018). Ceramic hyperbranched alkyd/γ-Al2O3 nanorods composite as a surface coating. Progress in Organic Coatings, 120, 217-227.

Dal Lago E, Cagnin E, Boaretti C, Roso M, Lorenzetti A, & Modesti M. (2019). Influence of different carbon-based fillers on electrical and mechanical properties of a PC/ABS blend. Polymers, 12, 29.

Venkatachalam S, Zeranska‐Chudek K, Zdrojek M, & Hourlier D. (2020). Carbon‐based terahertz absorbers: Materials, applications, and perspectives. Nano Select., 1, 471-490.

Singh AK, Panda BP, Mohanty S, Nayak SK, & Gupta MK. (2018). Recent developments on epoxy-based thermally conductive adhesives (TCA): A review. Polymer-Plastics Technology and Engineering, 57, 903-934.

Kumar R, Mishra A, Sahoo S, Panda BP, Mohanty S, & Nayak SK. (2019). Epoxy‐based composite adhesives: effect of hybrid fillers on thermal conductivity, rheology, and lap shear strength. Polymers for Advanced Technologies, 30, 1365-1374.

M. Saoudi, R. Ajjel, & B. Zaidi. (2017). Recent progress in organic nano-composites: Synthesis and treatments for use as active layers in electronic devices. Int. J. Exp. Res. Rev., 9, 11-46.

Bossin L, Bailiff I, & Terry I. (2020). Radiological emergency dosimetry–the use of luminescent mineral fillers in polymer-based fabrics. Radiation Measurements, 134, 106318.

Lou M, Chen X, Xu K, Deng Z, Chen L, & Lv J, et al. (2021). Temperature-induced wear transition in ceramic-metal composites. Acta Materialia, 205, 116545.

D. M. Patel, & A. H. Gandhi. (2024). Experimental investigation and optimization of forming parameters in single point incremental forming of AZ31 magnesium alloy. IJERR, 46, 240–252.

Liu Z, Lei Q, & Xing S. (2019). Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. Journal of Materials Research and Technology, 8, 3741-3751.

Caccia M, Tabandeh-Khorshid M, Itskos G, Strayer A, Caldwell A, & Pidaparti S, et al. (2018). Ceramic–metal composites for heat exchangers in concentrated solar power plants. Nature, 562, 406-409.

J. O. Oniore, & P. O. Irikefe. (2025). Environmental degradation channels and economic growth in Nigeria (1990-2023). IJERR, 47, 174–185.

Singh A, & Jayswal S. (2021). Mechanical characterization of TiO2 nanoparticles based on glass fiber reinforced polymer composite. in: IOP Conference Series: Materials Science and Engineering, pp. 012006.

Khan M, Srivastava S, & Gupta M. (2021). Characterization of TiO2 microparticle-blended polymer-based hybrid wood particulate composites. Mechanics of Composite Materials, 57, 247-256.

A. Kumar, R. Kumar, & A. Kumar. (2024). Study of wear rate of AA7050-7.5 B4C-T6 composite and optimization of response parameters using taguchi analysis. Int. J. Exp. Res. Rev., 39, 73-81.

Deka BK, & Maji TK. (2011). Effect of TiO2 and nanoclay on the properties of wood polymer nanocomposite. Composites Part A: Applied Science and Manufacturing, 42, 2117-2125.

Srivastava S, & Tiwari RK. (2012). Synthesis of epoxy-TiO2 nanocomposites: A study on sliding wear behavior, thermal and mechanical properties. International Journal of Polymeric Materials, 61, 999-1010.

S. M. Sundararajan, & M. Mani. (2024). Biodegradable edible microbial cellulose-based film for sustainable packaging from lab to land: Physicomechanical study. Int. J. Exp. Res. Rev., 39, 142-153.

Saba N, Tahir PM, & Jawaid M. (2014). A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers, 6, 2247-2273.

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Imran M Quraishi, Sanjay B Chikalthankar

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.