Optimizing Wear Resistance in Composite Materials: Surface Response Methodology

DOI:

https://doi.org/10.5281/zenodo.15574061Keywords:

tungsten-copper-composites, wear rate optimization, box-behnken design, response surface methodology, design of experiments (doe)Abstract

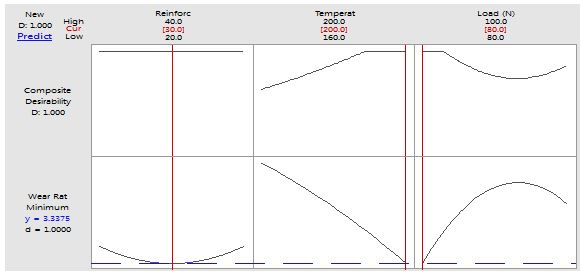

In This research aims to use Response Surface Methodology (RSM) in determining the settings that give the highest wear resistance of the developed (Cu-W) composites by varying reinforcement percentage at 20-40%, temperature at 160-200°C and mechanical load at 80-100N. A regression analysis was carried out to determine the parameters that affect wear rate and indicated that temperature and Cu-W percentage are significant factors affecting the wear rate with p total values 0.017 is significant. Optimization result suggested that at 30% Cu, 200°C and 80N load has the highest desirability of 1.00 with the best wear rate is 3.498 mm3/Nm. Contour and surface plots were used to further elaborate on synergy between the factors. The results of this study will be valuable for creating the adequate Cu-W composites composition that has decent durability in the applications that require the use of electric contacts and tools for high temperatures, in which wear is of great importance. This, therefore, shows how RSM is effective in optimizing the material with minimum experimental runs.

Downloads

References

Nithesh, R., Radhika, N., & Shiam Sunder, S. (2017). Mechanical properties and adhesive scuffing wear behaviour of stir cast Cu-Sn-Ni/Si₃N₄Composites. Journal of Tribology. doi:10.1115/1.4036185.

R., Sreenivasa, B. T. Ramesh, Giri, J., Al-Sadoon, M. K., Bongale, A. K., Sathish, T., & Banagar, A. R. (2024). Optimizing process parameters to minimize wear-induced material loss in bronze-based hybrid metal matrix composites using the Taguchi method. AIP Advances, 14, 095104. doi:10.1063/5.0203081.

Clinktana, R., Senthil, V., Ramkumar, K. R., Sivasankar, S., & Al-Mufadi, F. A. (2019). Influence of B₄C nanoparticles on mechanical behavior of Silicon brass nanocomposite through mechanical alloying and hot pressing. Ceramics International. doi:10.1016/j.ceramint.2019.06.094.

Ahmed, I. M., Nayl, A. A., & Daoud, J. A. (2012). Leaching and recovery of zinc and copper from brass slag by sulfuric acid. Journal of Saudi Chemical Society. doi:10.1016/j.jscs.2012.11.003.

Deaquino-Lara, R., Soltani, N., Bahrami, A., Gutiérrez-Castañeda, E., García-Sánchez, E., & Hernández-Rodríguez, M.

A. L. (2014). Tribological characterization of Al7075-graphite composites fabricated by mechanical alloying and hot extrusion. Materials and Design, 58, 9-17. doi:10.1016/j.matdes.2014.11.045.

Jeon, C. S., Jeong, Y. H., Hong, S. T., Hasan, M. T., Tien, H. N., Hur, S. H., & Kwon, Y. J. (2013). Mechanical properties of graphite/aluminum metal matrix composite joints by friction stir spot welding. Journal of Mechanical Science and Technology, 28(2), 499-504. doi:10.1007/s12206-013-1153-0.

Das, Somnath, & Parthadeb Ghosh. (2022). Plant regeneration through somatic embryogenesis of pseudostem callus culture response in in-vitro condition of palmarosa grass (Cymbopogon martinii) with special reference to hardening and pot culture. International Journal of Experimental Research and Review, 25-29. https://doi.org/10.52756/ijerr.2022.v28.004.

Parikh, V. K., Patel, V., Pandya, D. P., & Andersson, J. (2023). Current status on manufacturing routes to produce metal matrix composites. Heliyon. doi:10.1016/j.heliyon.2023.e13558.

Alam, M. A., Ya, H. H., Ahmad, A., Yusuf, M., Azeem, M., & Masood, F. (2021). Influence of aluminum addition on the mechanical properties of brass/Al composites fabricated by stir casting. Materials Today: Proceedings. doi:10.1016/j.matpr.2021.02.321.

Kumar, S., Nandal, A., Kundu, R., & Rakesh, (2020). Study of mechanical properties of rock dust and brass MMC. Journal of Materials Research and Technology. doi:10.1016/j.jmrt.2020.01.045.

Zhang, Z., Liu, C. K., Yu, Z. L., & Li, J. Y. (2024). The fabrication of brass reinforced aluminum matrix composites by friction stir welding. Journal of Materials Research and Technology. doi:10.1016/j.jmrt.2024.07.062.

Arisgraha, Irene Angela, Nuzulian Akbar Arandana, & Bondan Tiara Sofyan. (2018a). Effects of aluminum addition on the characteristics of Cu-28Zn brass produced by gravity casting. https://doi.org/10.1088/1757-899X/285/1/012031.

Aydin Gunes, Ömer Sinan Şahin, Hayrettin Düzcükoğlu, Emin Salur, Abdullah Aslan, Mustafa Kuntoğlu, Khaled Giasin, & Danil Yurievich Pimenov. (2021a). Optimization study on surface roughness and tribological behavior of recycled cast iron reinforced bronze MMCs produced by hot pressing. https://www.mdpi.com/1996- 1944/14/12/3364/pdf.

Dusoe, Keith J., Sriram Vijayan, Thomas R. Bissell, Jie Chen, Jack E. Morley, Leopolodo Valencia, Avinash M. Dongare, Mark Aindow, & SeokWoo Lee. (2017). Strong, ductile, and thermally stable cu-based metal-intermetallic nanostructured composites. Scientific Reports. Nature Portfolio. https://doi.org/10.1038/srep40409.

Jamwal, Anbesh, Prem Prakash Seth, Devendra Kumar, Rajeev Agrawal, Kishor Kumar Sadasivuni, & Pallav Gupta. (2020). Microstructural, tribological and compression behaviour of copper matrix reinforced with graphite -SiC hybrid composites. Materials Chemistry and Physics. Elsevier BV. https://doi.org/10.1016/j.matchemphys.2020.123090.

Jin-Su Ha, Jae-Hee Hong, Ji-Wook Kim, Sen Han, Chang Kyoung Choi, Hyun Keun Song, Jin-Seok Jang, Dong-Yul Kim, Dae-Cheol Ko, Yi Sangbong, & Yong-Jae Cho. (2023a). The effect of Boron (B) and Copper (Cu) on the microstructure and graphite morphology of spheroidal graphite cast iron. https://www.mdpi.com/1996- 1944/16/12/4225/pdf?version=1686132585.

Manvandra Kumar Singh, Rakesh Kumar Gautam, Rajiv Prakash, & Gopal Ji. (2018b). Mechanical and corrosion behaviors of developed copper-based metal matrix composites. https://doi.org/10.1088/1757-899X/330/1/012021.

Patel, D. M., & Gandhi, A. H. (2024). Experimental investigation and optimization of forming parameters in single point incremental forming of AZ31 magnesium alloy. International Journal of Experimental Research and Review, 46, 240–252. https://doi.org/10.52756/ijerr.2024.v46.019.

Kumar, Arvind, Ranveer Kumar, & Abhishek Kumar. (2024). Study of wear rate of AA7050-7.5 B4C-T6 composite and optimization of response parameters using taguchi analysis. International Journal of Experimental Research and Review 39 (Spl. Volume), 73-81. https://doi.org/10.52756/ijerr.2024.v39spl.005.

Nazeer, Faisal, Zhuang Ma, Lihong Gao, Abdul Malik, Sehreish Abrar, Fuchi Wang, & Hezhang Li. (2020). Effect of graphite mesh sizes on thermo-mechanical properties of Cu-GF composites. Vacuum. Elsevier BV. https://doi.org/10.1016/j.vacuum.2020.109989.

Raed N. Razooqi. (2023b). Mechanical and physical properties of a hybrid composite with basis of aluminum. https://tjps.tu.edu.iq/index.php/tjps/article/download/780/439.

Victor Verbiţchi, Lia Boțilă, Cristian Ciucă, Ana Kostov, Aleksandra Milosavljević, & Radiša Todorović. (2015). Improving a brazed joint structure, with a new ecological brass. https://www.scientific.net/AMR.1111.19.

Patel, D. M., & Gandhi, A. H. (2024). Experimental investigation and optimization of forming parameters in single point incremental forming of AZ31 magnesium alloy. International Journal of Experimental Research and Review, 46, 240–252. https://doi.org/10.52756/ijerr.2024.v46.019.

Yang, Ziyue, Fan Deng, Zhang Tao, Shuai Yan, Heng Ma, Miao Qian, Wei He, Zhifeng Zhang, Yanqiang Liu, & Lidong Wang. (2023). Effects on the microstructure evolution and properties of graphene/copper composite during rolling process. Materials. Multidisciplinary Digital Publishing Institute. https://doi.org/10.3390/ma16165534.

Yu, Ting, Fengping Zhong, Fang Zhang, Chenkai Ying, & Guihong Geng. (2021). Application of scanning electron microscopy in metal material detection. Journal of Physics Conference Series. IOP Publishing. https://doi.org/10.1088/1742-6596/2002/1/012010.

Zeng, Jun, Jincheng Xu, Hua Wei, Long Xia, Xiaoyan Deng, Sen Wang, & Peng Tao, et al. (2009). Wear performance of the lead free tin bronze matrix composite reinforced by short carbon fibers. Applied Surface Science. Elsevier BV. https://doi.org/10.1016/j.apsusc.2009.02.063.

Zhang, Xin, Chen Ma, Shufeng Li, Deng Pan, & Feiyang Zheng. (2020). Interface design of lead-free free- cutting titanium reinforced graphite brass composites and its effect on mechanical properties and cutting performance. Materials Science and Engineering A. Elsevier BV. https://doi.org/10.1016/j.msea.2020.138909.

Das, R., Sow, P., Dey, S., & Samadder, A. (2020). A brief overview on role of graphene based material in therapeutic management of inflammatory response signalling cascades. Int. J. Exp. Res. Rev., 21, 25-36. https://doi.org/10.52756/ijerr.2020.v21.004.

Patel, Dharmin M, & Anishkumar H Gandhi. (2024). Experimental investigation and optimization of forming parameters in single point incremental forming of AZ31 magnesium alloy. International Journal of Experimental Research and Review, 46, 240-52. https://doi.org/10.52756/ijerr.2024.v46.019.

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Chandrashekhar Ingle, Aniruddh Nikalje

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.