Performance Assessment of Concrete Using Paper and Wastewater Sludge to Replace Part of the Cement

DOI:

https://doi.org/10.5281/zenodo.14988569Keywords:

cement partial replacement, paper mill sludge, wastewater sludge, compressive strength, split tensile strength, co2 emissions, workability, absorbed waterAbstract

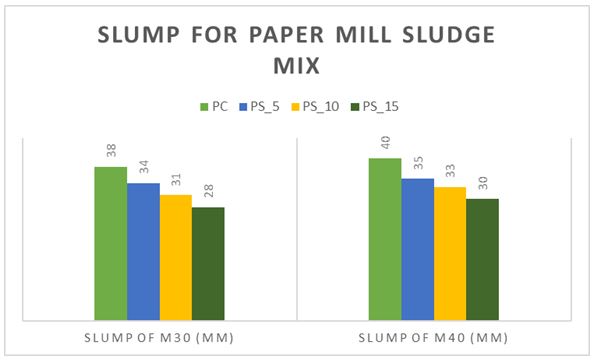

Along with deforestation and the use of fossil fuels, the cement manufacturing sector contributes significantly to carbon dioxide (CO₂) emissions. Additionally, the concrete industry is one of the major consumers of natural raw resources, which has an impact on environmental sustainability. In order to tackle these issues, this study examines the effects of partially substituting paper mill and wastewater sludge for cement in weight percentages of 5%, 10%, and 15% on the compressive, split tensile, and flexural strengths of concrete at 7 and 28 days of curing. According to experimental data, the 5% replacement mix showed better mechanical qualities than the control mix (0% replacement), suggesting that it could be a sustainable option in the manufacturing of concrete, even though higher replacement levels resulted in a decrease in strength. Strength was shown to decrease after 5%, underscoring the drawbacks of adding too much sludge. The viability of using industrial by-products in concrete to lessen reliance on cement and CO₂ emissions while preserving structural integrity is clarified by this study. By encouraging the use of waste materials in cement-based composites, the findings support the continuous efforts towards sustainable construction methods.

Downloads

References

Dincă, C., & Slavu, N. (2025). Integrating P2M-CC for sustainable decarbonization in cement manufacturing. https://doi.org/10.20944/preprints202501.1151.v1

Jindal, A. (2024). Sustainable construction materials: Evaluating the performance and environmental impact of recycled aggregates in concrete. Deleted Journal, 12(4), 25–32. https://doi.org/10.36676/dira.v12.i4.157

Feng Q, Gao B, Yue Q, & Guo K. (2021). Flocculation performance of papermaking sludge -based flocculants in different dye wastewater treatment: Comparison with commercial lignin and coagulants. Chemosphere, 262. https://doi.org/10.1016/j.chemosphere.2020.128416

Guo K, Gao B, Wang J, Pan J, Yue Q, & Xu X. (2021). Flocculation behaviors of a novel papermaking sludge -based flocculant in practical printing and dyeing wastewater treatment. Front Env Sci Eng, 15(5). https://doi.org/10.1007/s11783-021-1390-x

Zahraa Jwaida, Anmar Dulaimi, Wajde Alyhya, Hayder Algretawee, & Shakir Al-Busaltan. (2024). Recycling and utilization of paper sludge ash -current status review and future perspectives. Sustainable Materials and Technologies, 40. https://doi.org/10.1016/j.susmat.2024.e00960

Kon M, & Chou L. (2014). The Eco-concrete with the Papermaking Sludge. Applied Mechanics, Materials and Manufacturing, IV, 670–671. https://doi.org/10.4028/www.scientific.net/AMM.670-671.454

Srivastava S, Moukannaa S, Isteri V, Ramteke DD, Perumal P, Adesanya D, Kinnunen P, Ohenoja K, & Illikainen M. (2024). Utilization of calcite-rich Green Liquor Dregs (GLD) by-products from pulp and paper industry: cement clinker production and life cycle analysis. Case Stud. Constr Mater, 20. https://doi.org/10.1016/j.cscm.2024.e02870

Shi D, Xia Y, Zhao Y, Liu M, & Yang Y. (2024). Controllable setting time of alkali-activated materials incorporating sewage sludge ash and GGBS: the role of retarders. Constr Build Mater, 412. https://doi.org/10.1016/j.conbuildmat.2023.134857

Lin K, Lin DF, & Luo HL. (2009). Influence of phosphate of the waste sludge on the hydration characteristics of eco-cement. J Hazard Mater 168, 2-3. https://doi.org/10.1016/j.jhazmat.2009.02.149

Sumit Chakraborty, Byung Wan Jo, Jun Ho Jo, & Zafar Baloch. (2017). Effectiveness of sewage sludge ash combined with waste pozzolanic minerals in developing sustainable construction material: An alternative approach for waste management. Journal of Cleaner Production, 153. https://doi.org/10.1016/j.jclepro.2017.03.059

Barbora Krejcirikova, Lisbeth M. Ottosen, Gunvor M. Kirkelund, Carsten Rode, & Ruut Peuhkuri. (2019). Characterization of sewage sludge ash and its effect on moisture physics of mortar. Journal of Building Engineering, 21, 396-403. https://doi.org/10.1016/j.jobe.2018.10.021

Rodrigues, Flávio & Joekes, I. (2010). Cement industry: Sustainability, challenges and perspectives. Environmental Chemistry Letters, 9, 151-166. http://dx.doi.org/10.1007/s10311-010-0302-2

Lin Chen, Mingyu Yang, Zhonghao Chen, Zhuolin Xie, Lepeng Huang, Ahmed I. Osman, Mohamed Farghali, Malindu Sandanayake, Engui Liu, Yong Han Ahn, Ala'a H. Al-Muhtaseb, David W. Rooney, & Pow-Seng Yap. (2024). Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Materials Today Sustainability, 27, 100930. https://doi.org/10.1016/j.mtsust.2024.100930

Jeong-Bae Lee. (2024). Incorporating wastewater sludge as a cement alternative in repair mortar: An experimental study of material properties. Materials, 17(22), 5625. https://doi.org/10.3390/ma17225625

Saif Saad Mansoor, Sheelan Mahmoud Hama, & Dhifaf Natiq Hamdullah. (2024). Effectiveness of replacing cement partially with waste brick powder in mortar. Journal of King Saud University - Engineering Sciences, 36(7), 524-532. https://doi.org/10.1016/j.jksues.2022.01.004

Ignacio Zabalza Bribián, Antonio Valero Capilla, & Alfonso Aranda Usón. (2011). Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Building and Environment, 46(5), 1133-1140. https://doi.org/10.1016/j.buildenv.2010.12.002

Bui, P. T. (2022). Effect of partial replacement of cement by waste sludge from water supply plant on compressive strength and water absorption of hardened concrete, pp. 419–427. https://doi.org/10.1007/978-981-19-3303-5_35

Zari, R., Graich, A., Abdelouahdi, K., Monkade, M., Laghzizil, A., & Nunzi, J.-M. (2023). Mechanical, structural, and environmental properties of building cements from valorized sewage sludges. Smart Cities, 6(3), 1227–1238. https://doi.org/10.3390/smartcities6030059

Thukkaram, S., & Ammasi, A. K. (2024). Behaviour of sewage sludge based lightweight aggregate in geopolymer concrete. Materials Research Express. https://doi.org/10.1088/2053-1591/ad4198

I.S. 12269-1987 Specification for 53 grade ordinary Portland cement.

I.S. 383-1970 Specification for coarse and fine aggregates from natural source for concrete.

I.S. 456-2000 Indian standard plain and reinforced concrete – code of practice.

I.S. 2386-1963 Methods of test for aggregates for concrete.

I.S. 10262-2009 Recommended guidelines for concrete mix design.

I.S. 4031-1988 Method for physical test forcement: part 5 Determination of initial and final setting times.

I.S: 3025-1964 - Methods of sampling and test (physical and chemical) for water and wastewater.

IS 516 (1959): Method of tests for strength of concrete.

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2025 Siva Teja Sowrya Yannana, Dr. Saroja Rani Kesanapalli, Tanuja Velamakayala

This work is licensed under a Creative Commons Attribution 4.0 International License.

Research Articles in 'Applied Science and Engineering Journal for Advanced Research' are Open Access articles published under the Creative Commons CC BY License Creative Commons Attribution 4.0 International License http://creativecommons.org/licenses/by/4.0/. This license allows you to share – copy and redistribute the material in any medium or format. Adapt – remix, transform, and build upon the material for any purpose, even commercially.