A Study on FRP-Reinforced Concrete Structures

Prabhakar S1*, Amit R2

DOI:10.54741/asejar.1.1.1

1* Sangave Prabhakar, Pg Student, Department of Civil Engineering, Walchand Institute of Technology, Solapur, India.

2 Rao Amit, PG Student, Department of Civil Engineering, Walchand Institute of Technology, Solapur, India.

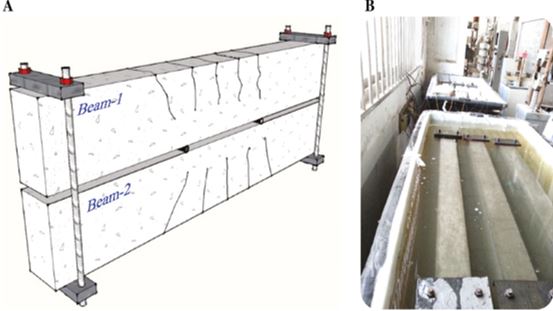

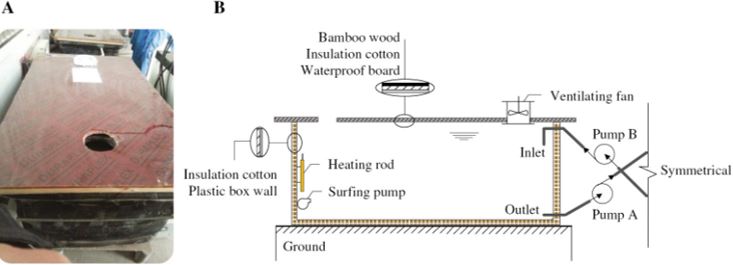

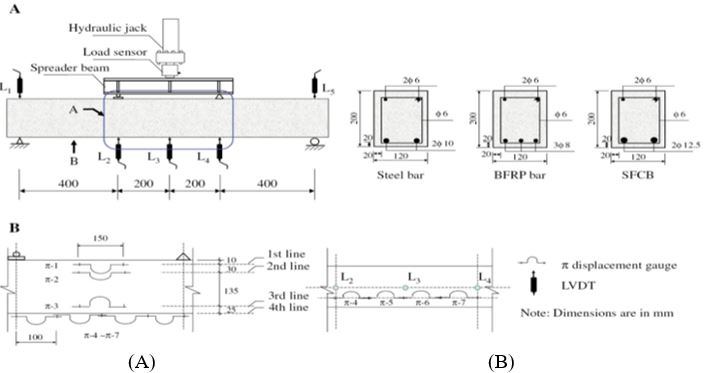

In civil engineering, fiber reinforced polymer (FRP) bars are commonly employed. As an alternative to reinforcement steel due to their numerous advantages, including great weight-to-strength ratio, light weight, ease of handling electromagnetic neutrality, and lack of rust. Furthermore, as production machinery develops and more becomes industrialized, FRP has evolved into a cost-effective and competitive structural material. This work examines flexural presentation of fiber-reinforced polymer (FRP) bars and concrete reinforced (RC) after beams conditioning for 6, 9, and 12 months simulated seawater in a wet-dry environment cycling. The purpose of this study is to introduce advancements in the research on FRP-reinforced concrete structures based on recent research. The bond presentation of FRP bars flexural behaviour, concrete, compression behaviour, and concrete of ductility structures reinforced with FRP bars in the last few years around the world are among the topics covered in this study. steel-FRP composite bars (SFCBs) and Basalt FRP (BFRP) are the two types of FRP bars used. For comparison, steel bars are used. During the conditioning, the beams are subjected to a steady load. There are a full of 24 simple-supported rays that being verified.

Keywords: FRP-reinforced, concrete structures, reinforce bar, bond strength

| Corresponding Author | How to Cite this Article | To Browse |

|---|---|---|

| , Pg Student, Department of Civil Engineering, Walchand Institute of Technology, Solapur, , India. Email: |

Prabhakar S, Amit R, A Study on FRP-Reinforced Concrete Structures. Appl. Sci. Eng. J. Adv. Res.. 2022;1(1):1-6. Available From https://asejar.singhpublication.com/index.php/ojs/article/view/2 |

©

©